Teoria przepływu powietrza

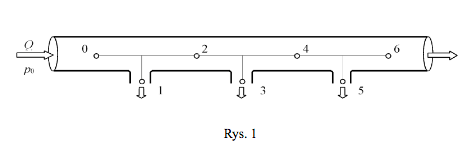

Wzdłuż kanału tekstylnego wykonane są otworki o jednakowej średnicy. Określamy wydatki wypływu z otworków Q1 , Q3 , Q5 itd. oraz ciśnienia wzdłuż przewodu, jeśli przed otworkami ciśnienie wynosi p0 , a wydatek przepływu wynosi Q. Uwzględnione zostały opory przepływu, czyli przyjęto, że płyn nie jest idealny. Pole przekroju przewodu wynosi A, zaś pole otworka A1

Przyjmijmy punkty kontrolne w osi przewodu i na zewnątrz otworków (rys. 1).

Dla płynów rzeczywistych (lepkich) równanie Bernoulliego dane jest wzorem:

p0 + ½ρU02α = pi + ½ρUi2α + γHs,

gdzie α jest współczynnikiem korekcyjnym dla energii kinetycznej przepływu, γ = ρg jest ciężarem właściwym płynu, U = Q/A jest średnią prędkością przepływu na danym odcinku przewodu, zaś Hs jest wysokością strat. W zakresie turbulentnym, gdy liczba Reynoldsa Re ≡ Ud/ν • 2300, gdzie d jest średnicą wewnętrzną rurociągu, zaś ν [m2/s] jest kinematycznym współczynnikiem lepkości, współczynnik korekcyjny ma wartość:

α ∈ 〈1,05, 1,1〉

Wyrażenie po lewej stronie równania Bernoulliego ma znaczenie pmax. Stąd wzór ten można zapisać analogicznie, jak poprzednio:

pmax = pi + ½ρUi2α + γHs,

gdzie pmax = p0 + ½ρU02α. Wysokość strat dana jest wzorem: Hs = −Δp/γ, czyli

γHs = −Δp.

Wyraz γHs jest zatem równy spadkowi ciśnienia wzdłuż rurociągu. Przepływ płynu przez rurociąg wiąże się zawsze ze spadkiem ciśnienia, czyli wzrostem wysokości strat Hs. Twierdzenie to jest analogiczne do twierdzenia Ohma w elektrotechnice: przepływ prądu przez przewodnik wiąże się ze spadkiem napięcia. Inaczej mówiąc, nie może być przepływu płynu rzeczywistego w rurociągu bez spadku ciśnienia. Tym samym, ciśnienie wzdłuż przewodu stale spada (a wysokości strat rośnie), bez względu na konfigurację rurociągu.

Różnica ciśnień na odcinku l, wywołana tarciem, dana jest wzorem:

−Δpst = λ½ρU2l/d = cR½ρU2,

gdzie λ = λ(Re) jest współczynnikiem strat tarcia, zależnym od liczby Reynoldsa Re = Ud/ν, zaś cR = λl/d jest współczynnikiem oporu przepływu przez rurociąg. Dla przepływu turbulentnego współczynnik λ wyznacza się empirycznie, za pomocą systematycznych badań doświadczalnych. Według Blasiusa:

λ = 0,3164/Re1/4.

Gradient ciśnienia −Δpst/l na poszczególnych odcinkach przewodu

−Δpst/l = λ½ρU2/d

nie jest stały, co widać ze wzoru; zależy bowiem od średnicy przewodu d i liczby Reynoldsa Re, które zmieniają się odcinkami.

Obok strat tarcia wyróżnia się tzw. straty lokalne Δpsl. Występują one w tych fragmentach przewodu, gdzie zmianie ulega prędkość przepływu lub kierunek, a więc w krzywakach i kolankach, zaworach, zwężkach, kryzach, u wlotu (wylotu) ze zbiornika do przewodu itp. Główną przyczyną tych strat są intensywne ruchy wirowe i związana z tym dysypacja energii, zwiększona w porównaniu z przepływem przez prostoosiowy odcinek przewodu o stałej średnicy, a długości tej samej, co element na którym występuje strata lokalna (dławienie).

Można łatwo pokazać, że przy zadanym wydatku przepływu Q = const, straty tarcia −Δpst ∼ d−4,75. Przykładowo, jeśli średnica zmaleje dwukrotnie, to opory przepływu wzrosną 24,75 ≈ 26,9 raza. W tej samej proporcji zmieni się moc pompowania, dana wzorem: N = −QΔp.

W sposób analogiczny do straty na tarcie wyraża się także stratę lokalną, zdefiniowaną wzorem:

−Δpsl = ζ½ρU2,

gdzie ζ = ζ(Re, k/d) zależy nie tylko od liczby Reynoldsa lecz także od chropowatości.

Przechodząc do naszego zadania, przyrównując sumę w punkcie „0” i w punkcie zewnętrznym dowolnego otworka w równaniu Bernoulliego, np. otworka 3., otrzymamy równanie na prędkość wypływu z tego otworka:

p0 + ½ρU02α = pa + κ½ρv32 − Δpst0 − Δpst2,

pmax − pa + (Δpst0 + Δpst2) = κ½ρv32,

gdzie pmax = p0 + ½ρU02α, zaś κ jest współczynnikiem wypływu, jak w przypadku wypływu przez otwór w zbiorniku. Otworki pełnią rolę trójników, których straty możemy pominąć, dlatego równanie nie uwzględnia ich. Uwzględnia jedynie straty tarcia na poszczególnych odcinkach przewodu: −Δpst0 = λ0½ρU02l0/d, −Δpst2 = λ2½ρU22l2/d, gdzie U0 = Q/A, U2 = (Q – Q1)/A są średnimi prędkościami przepływy na poszczególnych odcinkach przewodu.

Z równania widać, że – w odróżnieniu od płynu nielepkiego – prędkość wypływu z kolejnych otworków, a tym samym wydatek przepływu jest coraz mniejszy.

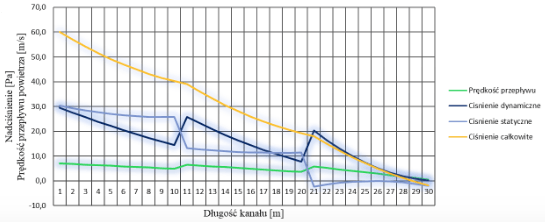

Dla ilustracji, wykonano obliczenia dla przepływu gazu lepkiego przewodem stopniowanym, jak na rys. 2. Na rys. 4 przedstawiono przebieg ciśnienia całkowitego (monotonicznie opada), ciśnienia statycznego, dynamicznego i prędkości przepływu powietrza w przewodzie.

Dr hab. inż. Maciej Pawłowski

W związku z powyższa teorią, zapewniamy równomierne rozłożenie ciśnienia dynamicznego i statycznego na całej długości kanału. W tym celu stosuje się redukcje średnic, dzięki czemu kanał jest równomiernie napompowany oraz nie występuje zjawisko pulsowania.